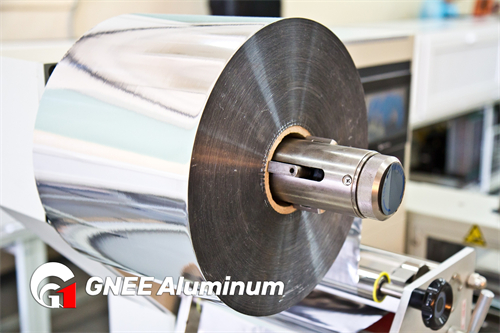

Aluminum foil for lamination Manufacturer And Whosaler

$1800-2200 /Ton

| Payment Type: | L/C,D/P,T/T,D/A,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS |

| Min. Order: | 2 Ton |

| Transportation: | Ocean,Land |

$1800-2200 /Ton

| Payment Type: | L/C,D/P,T/T,D/A,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS |

| Min. Order: | 2 Ton |

| Transportation: | Ocean,Land |

Model No.: 1235, 3003, 8011, 8079, 8021

Status: Half Hard

Use: Pharmaceutical

Shape: Roll

Place Of Origin: China

Alloy: 1000 ( pure aluminum ), 3000 , 800

Alu Temper:: O - H112 etc

Width:: 50mm - 1500mm

Thickness:: 0.006mm - 0.20mm

| Temper | O |

| Type | Lamination aluminium foil |

| Use | For different fod container applications |

| Certification | ISO, CE, ISO9001 |

| Brand | GNEE |

| Origian | HENAN |

| Elongation % | ≥1% |

| Grade | A |

| Packaging | Free fumiagated wooden box |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.